Comprehensive Guide to the Lincoln MIG 210 MP: The Ultimate Welding Solution for Cutting and Welding Equipment

When it comes to cutting and welding equipment, selecting a versatile and reliable machine is essential for achieving high-quality results in various industrial and DIY applications. The Lincoln MIG 210 MP has established itself as an industry-leading MIG/wire-feed welder, offering unmatched performance, flexibility, and ease of use. This in-depth guide aims to uncover why the Lincoln MIG 210 MP is considered a game-changer in the realm of welding technology, providing professionals and hobbyists with a comprehensive understanding of its features, benefits, and applications.

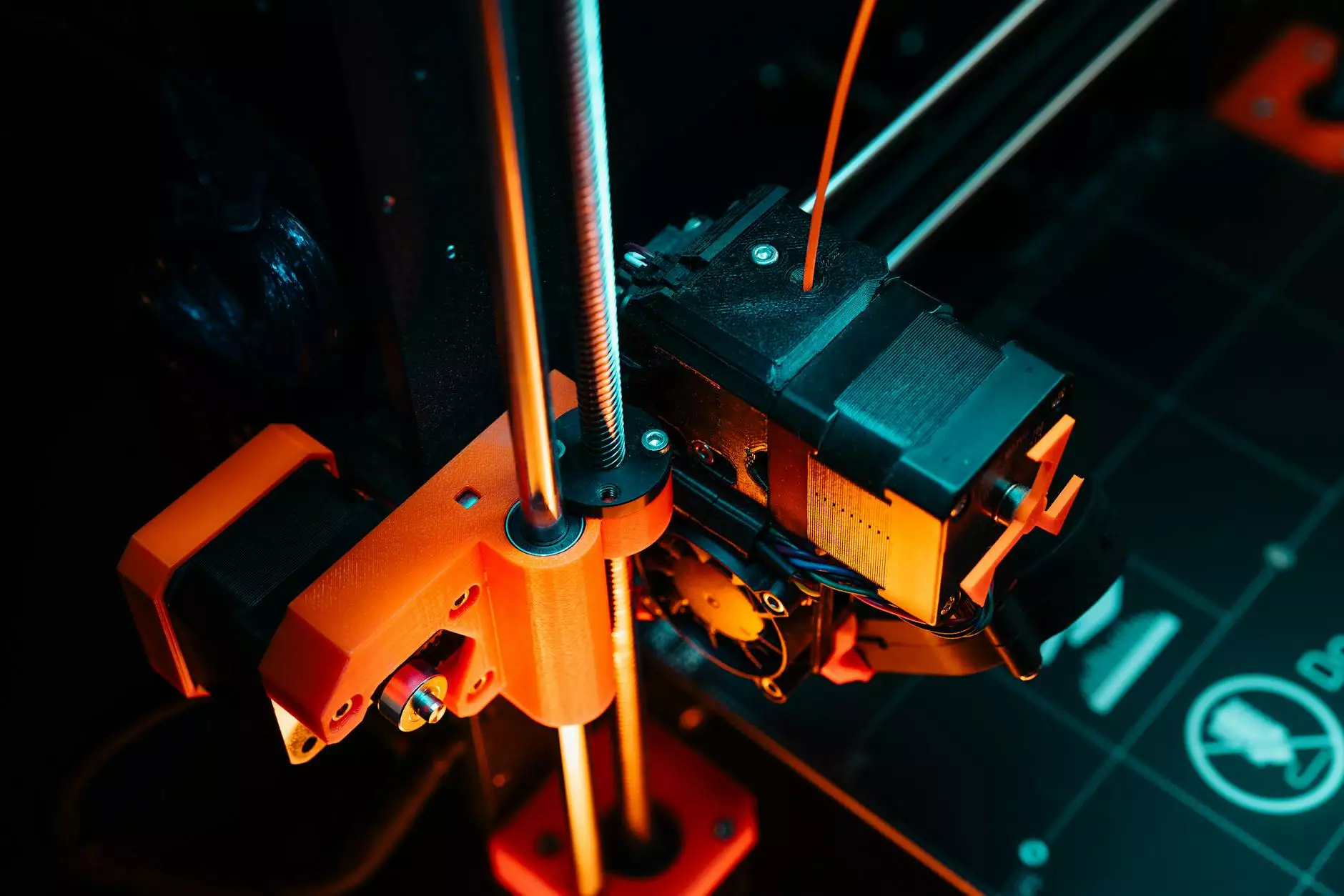

Introduction to the Lincoln MIG 210 MP: A Revolutionary Welding Machine

The Lincoln MIG 210 MP is a multi-process welding machine that seamlessly integrates MIG, flux-cored, stick, and TIG welding capabilities in a single device. Designed with innovative features and user-centric controls, this machine caters to a wide spectrum of welding tasks ranging from light repairs to heavy fabrication. Its versatility makes it an excellent choice for automotive work, construction, metal art, and industrial manufacturing.

Key Features of the Lincoln MIG 210 MP

- Multi-Process Flexibility: Supports MIG, flux-cored, stick, and TIG welding modes, allowing users to tackle a diverse array of projects.

- Powerful Performance: Equipped with a high output of 230V, enabling it to weld thick materials up to 3/8 inch with ease.

- Intuitive Digital Interface: Features an easy-to-navigate digital control panel for precision adjustments, setting parameters effortlessly.

- Portability and Compact Design: Despite its power, the machine boasts a portable build, ideal for on-site work and mobile workshops.

- Enhanced Cooling System: Efficient cooling ensures continuous operation during demanding tasks, prolonging the machine's lifespan.

- Built-In Hot Start and Arc Force Control: Facilitates quick arc starting and stable arcs, reducing spatter and improving weld quality.

- Dual Voltage Capability: Can operate on both 120V and 230V outlets, providing exceptional flexibility for various work environments.

Why the Lincoln MIG 210 MP Outshines Competitors in Cutting and Welding Equipment

The Lincoln MIG 210 MP is expressly designed to meet the rigorous demands of different welding projects, making it stand out from other machines. Here are compelling reasons why it surpasses its competitors in the cutting and welding equipment category:

1. Superior Multi-Process Capabilities

Unlike single-process welders, the Lincoln MIG 210 MP accommodates multiple welding techniques, significantly reducing the need for multiple machines. Whether you're performing MIG welding for automotive repairs, flux-cored welding for thick metals, or TIG welding for precision work, this machine consolidates all functionalities into a single, easy-to-use unit.

2. Rich Digital Control and Parameter Settings

The advanced digital interface enables precise adjustments to voltage, wire feed speed, and other parameters. This customization ensures optimal welds tailored to specific materials and thicknesses, leading to superior results every time.

3. Versatility Across Industries and Applications

Whether working indoors or outdoors, for small-scale artisan projects or large industrial fabrication, the Lincoln MIG 210 MP adapts efficiently. Its dual voltage feature and multiple process modes make it suitable for a broad spectrum of industries, including automotive, construction, manufacturing, maintenance, and hobbyist projects.

4. User-Friendly Experience for Beginners and Experts Alike

Industry professionals and novices alike benefit from the machine’s straightforward setup and operation. The clear digital menus, built-in safety features, and quick-change processes streamline the workflow, reducing learning curves and minimizing errors.

5. Durability and Reliability

Crafted with high-quality components, the Lincoln MIG 210 MP ensures longevity and dependable performance. Its robust construction withstands demanding environments, making it a long-term investment for any workshop or job site.

Detailed Breakdown of Lincoln MIG 210 MP Technical Specifications

To better understand its capabilities, here are the key technical specifications of the Lincoln MIG 210 MP:

- Power Supply: 120V / 230V dual voltage support

- Machine Type: Multi-process (MIG, flux-cored, stick, TIG)

- Input Amperage: 20-32A

- Welding Amperage Range: 40A – 210A

- Maximum Weld Thickness: Up to 3/8 inch (10 mm)

- Wire Feed Speed: 50-700 IPM (inches per minute)

- Cooling System: Built-in fan with temperature regulation

- Dimensions and Weight: Compact design weighing approximately 50 pounds

Application Scenarios Demonstrating the Power of the Lincoln MIG 210 MP

The adaptability of the Lincoln MIG 210 MP makes it suitable for a multitude of real-world applications:

- Automotive Repair and Fabrication: Ideal for welding car frames, exhaust systems, and custom parts due to its TIG and MIG capabilities.

- Construction and Structural Work: Can tackle thick steel beams, fences, and structural supports with ease.

- Metal Art and Hobbyist Projects: Perfect for artistic welds, sculptures, and DIY metal furniture, thanks to its precise control options.

- Industrial Maintenance: Facilitates quick repairs in factories, farms, or remote locations where portability is critical.

- Educational and Training Programs: Serves as an excellent teaching tool for academic instruction and vocational training due to its versatile features.

How to Maximize the Potential of the Lincoln MIG 210 MP

To get the most out of this sophisticated cutting and welding equipment, consider the following tips:

- Proper Setup: Always verify voltage compatibility and set the correct mode for your project to ensure optimal weld quality.

- Material Compatibility: Select the appropriate wire type and shielding gas depending on the workpiece material.

- Maintenance: Regularly clean the machine’s cooling vents, inspect for loose connections, and replace worn consumables to prolong lifespan.

- Practice and Calibration: Use scrap pieces to fine-tune settings before beginning critical welds, especially when switching between processes.

- Safety Precautions: Always wear appropriate personal protective equipment including helmet, gloves, and protective clothing.

Buying Guide: Why Choose the Lincoln MIG 210 MP from Tiendaguve.com

When investing in top-tier cutting and welding equipment, selecting a trusted supplier is crucial. Tiendaguve.com offers the Lincoln MIG 210 MP with comprehensive customer support, warranty services, and expert advice. Purchasing from a reputable dealer ensures genuine products, spare parts availability, and access to technical assistance, making your investment more secure and rewarding.

Conclusion: Elevate Your Welding Projects with the Lincoln MIG 210 MP

The Lincoln MIG 210 MP stands out as one of the most versatile, powerful, and user-friendly welding machines in the market. Its ability to accommodate various processes, underpinned by advanced digital controls and durable construction, makes it the ultimate cutting and welding equipment choice for professionals, hobbyists, and educational institutions alike. Embrace this technological marvel to elevate your craftsmanship, improve productivity, and achieve superior weld quality every time.

For those seeking a comprehensive, reliable, and adaptable welding solution, the Lincoln MIG 210 MP is undoubtedly a worthwhile investment. Explore the exceptional features and benefits by visiting Tiendaguve.com, your trusted partner in cutting and welding equipment.