Revolutionize Your Business with CNC Machines from roc-tech.com

In today's fast-paced industrial landscape, businesses are continually seeking innovative solutions to enhance productivity, improve efficiency, and stay ahead of the competition. One of the key technologies driving this evolution is CNC (Computer Numerical Control) machines. At roc-tech.com, we understand the critical role that CNC machinery plays in modern manufacturing processes. In this extensive article, we delve into the world of CNC machines for sale, exploring their benefits, applications, and why investing in these machines can be a game changer for your business.

What Are CNC Machines?

CNC machines are advanced tools that utilize computer programming to control machinery operations. These machines can be used for a variety of manufacturing purposes, such as:

- Milling - Removing material from a workpiece using rotary cutters.

- Turning - Rotating the workpiece against a single-point cutting tool.

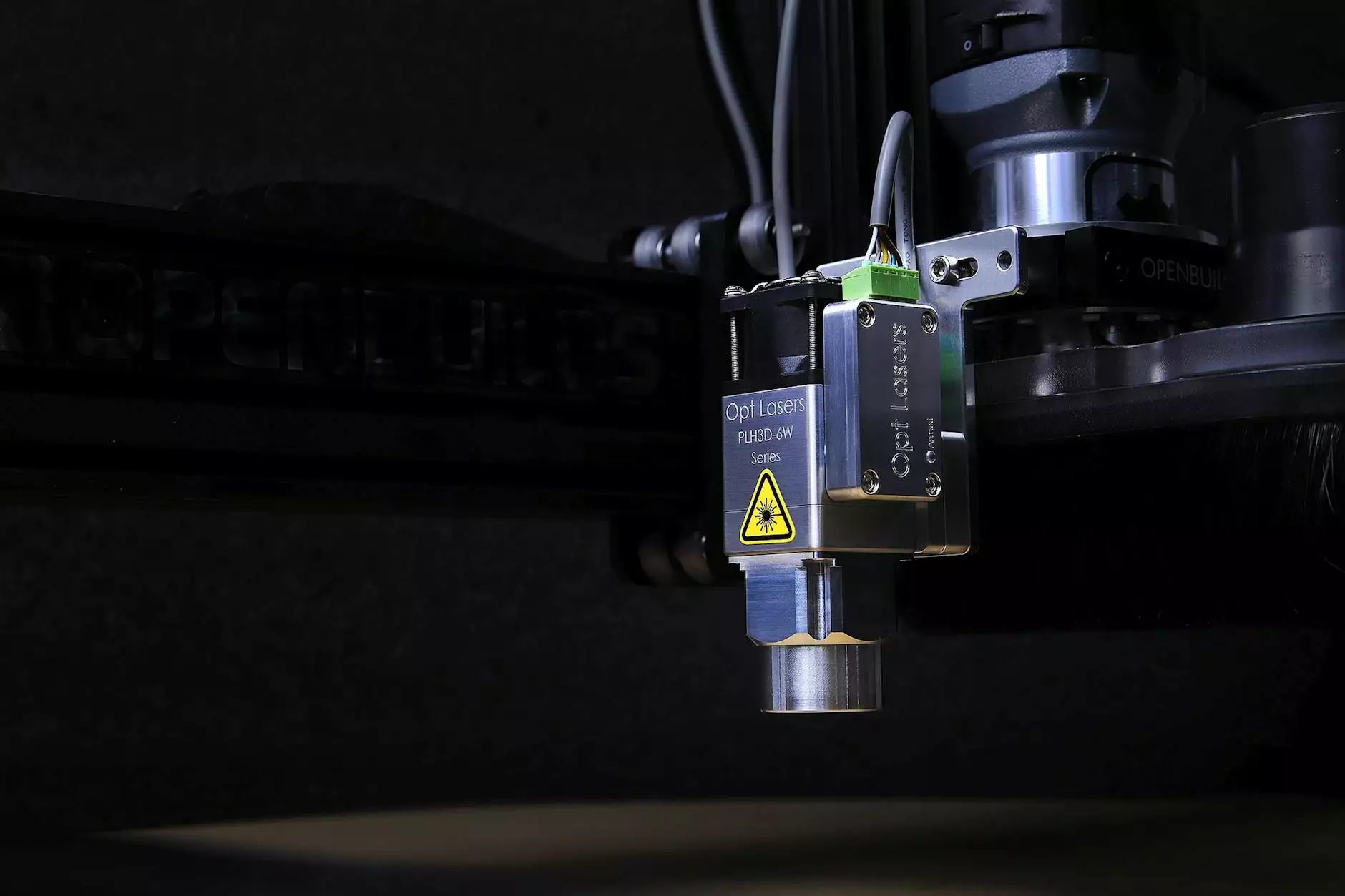

- Laser Cutting - Using a laser to cut materials with high precision.

- 3D Printing - Layering materials to create three-dimensional objects.

Benefits of CNC Machines

Investing in CNC machines offers numerous advantages for businesses across various industries. Here are some of the key benefits:

1. Enhanced Precision and Accuracy

One of the standout features of CNC machines is their ability to operate with high precision. Unlike manual machines, which are subject to human error, CNC machines can replicate complex parts with incredible accuracy. This precision significantly reduces waste and improves product quality, which is essential in competitive markets.

2. Increased Production Speed

Time is money in the manufacturing sector. CNC machines can operate continuously, often at a faster rate than manual machines. This high-speed operation means:

- Shorter lead times for production.

- Higher output during a defined period.

- Emission of consistent quality across all units produced.

3. Versatility in Applications

Another significant advantage of CNC machines is their versatility. A single CNC machine can perform various tasks, including cutting, shaping, drilling, and engraving. This versatility enables businesses to:

- Adapt quickly to market demands and changes.

- Produce a wide range of products using the same machinery.

4. Reduced Workplace Safety Risks

With manual machining, most workplace injuries occur due to human error or poor handling. CNC machines are designed to operate autonomously, therefore minimizing the risk of injury to workers. Advanced safety features and enclosures contribute further to creating a safer workplace environment.

Choosing the Right CNC Machine at roc-tech.com

With various CNC machines available in the market, selecting the right one for your business can be overwhelming. At roc-tech.com, we provide a detailed guide to help you make the right choice:

1. Understand Your Manufacturing Needs

Before choosing a CNC machine, it is crucial to assess what operations you need it for. Consider factors such as:

- Types of materials you will be working with (metal, wood, plastic, etc.)

- The complexity of the parts you need to produce.

- Your production volume and speed requirements.

2. Evaluate the Machine Specifications

Different CNC machines come with varying specifications. Some key aspects to consider include:

- Power rating: The machine's power affects productivity.

- Axis count: More axes provide more versatility.

- Size and footprint: Ensure it fits your workspace.

3. Technology and Software Integration

Modern CNC machines often come with sophisticated technology and software for programming and operation. Look for machines that offer:

- User-friendly interfaces

- Integration with CAD/CAM software

- Remote monitoring capabilities

Why Buy from roc-tech.com?

When it comes to investing in CNC machines, the supplier you choose can significantly impact your business's success. Here's why roc-tech.com stands out as a premier choice:

1. Extensive Product Range

At roc-tech.com, we offer a comprehensive selection of CNC machines, from entry-level models to advanced industrial machines. Our inventory caters to various industries, ensuring you will find the right machine tailored to your specific needs.

2. Quality Assurance

We prioritize quality. Each CNC machine sold at roc-tech.com undergoes strict quality control processes to ensure optimal performance and durability. Our products are built to last, supporting your business through its growth.

3. Expert Support and Consultation

Understanding CNC technology can be challenging. Our team of experts is here to provide you with personalized support and guidance. Whether you need help choosing the right machine or require assistance with setup and operation, we are committed to your success.

4. Competitive Pricing

At roc-tech.com, we believe that high-quality CNC machines should be accessible. Our competitive pricing ensures you receive the best value for your investment without compromising on quality.

Final Thoughts

Investing in CNC machines is a significant step towards enhancing your business's manufacturing capabilities. The ability to produce high-quality parts quickly and safely can set your business apart in a competitive landscape. Visit roc-tech.com today to explore our extensive range of CNC machines for sale and take your first step towards revolutionizing your production capabilities.

Take Action Now!

Don't wait any longer to transform your manufacturing processes. Visit roc-tech.com today and discover how our CNC machines can cater to your specific business needs. Together, let's build a more efficient and innovative future for your production.