Unleashing the Power of CNC Machining in Modern Metal Fabrication

In today's rapidly evolving manufacturing landscape, CNC machining stands out as a pivotal technology that redefines precision, efficiency, and scalability in metal fabrication. At DeepMould.net, our expertise in metal fabricators equipped with state-of-the-art CNC machinery ensures that clients receive unparalleled quality and customization for projects across myriad industries.

What Is CNC Machining and Why Is It Essential for Metal Fabrication?

CNC, or Computer Numerical Control, machining is an automated manufacturing process that utilizes computer programs to control machine tools. Unlike manual machining, CNC commands enable precise, repeatable cuts with minimal human intervention, ensuring consistency and high-quality outcomes.

Core Principles of CNC Machining

- Automation and Precision: CNC machines follow exact programmed instructions, reducing errors and waste.

- Versatility: Capable of machining a vast array of metals including steel, aluminum, brass, copper, and titanium.

- Complexity: Can produce intricate geometries and detailed features that are challenging with traditional methods.

- Efficiency: Increased throughput and minimized manual labor lead to faster project completion.

Advantages of CNC Machining in Metal Fabrication

Leveraging CNC machining delivers numerous benefits that significantly impact the entire production cycle:

1. Unmatched Precision and Accuracy

With tolerances often within ±0.01mm, CNC machining guarantees highly precise components crucial for aerospace, medical devices, automotive parts, and electronics.

2. Enhanced Repeatability and Consistency

Once a design is programmed, CNC machines can reproduce identical parts repeatedly, ensuring product uniformity in large production batches.

3. Reduced Lead Times

Automation accelerates manufacturing processes, minimizing turnaround times and enabling rapid prototyping and quick delivery to market.

4. Capable of Complex Geometries

From intricate curves to complex internal channels, CNC machining opens possibilities for innovative designs that push the boundaries of traditional fabrication techniques.

5. Cost-Effective Manufacturing

Although initial setup costs may be higher, long-term savings are significant due to reduced material waste, less manual labor, and minimized rework.

DeepMould.net’s Expertise in Metal Fabrication Using CNC Machining

DeepMould.net has established itself as a leader in metal fabricators that harness cutting-edge cnc machining technology. Our commitment to excellence, combined with advanced machinery and skilled technicians, ensures our clients receive products that exceed expectations.

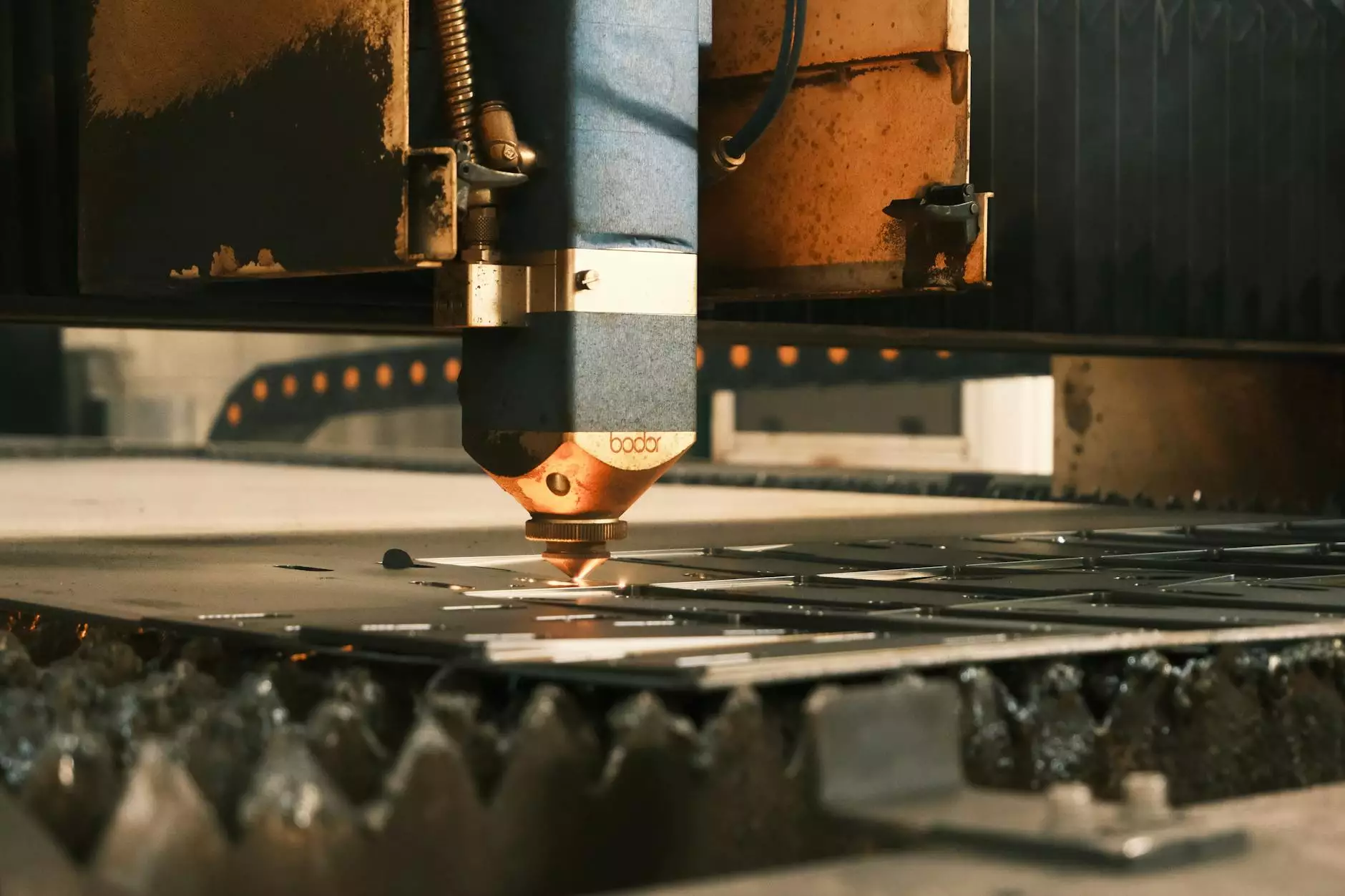

State-of-the-Art Equipment and Capabilities

- Wide Range of CNC Machines: Including CNC milling, turning, drilling, and EDM machines capable of handling diverse metals and complex parts.

- High-Precision Cutting: Achieving fine detail and tight tolerances for precise engineering applications.

- Rapid Prototyping: Transforming ideas into physical models swiftly for testing and validation.

- Mass Production: Efficiently producing large quantities of uniform components for automotive, aerospace, and industrial sectors.

Customized Solutions for Diverse Industries

Our certified metal fabricators tailor each project to meet unique specifications, whether it's a small batch of prototypes or large-scale manufacturing runs. We serve industries such as:

- Aerospace: High-strength, lightweight components with stringent tolerances.

- Medical Devices: Precisely machined parts that adhere to strict hygienic and safety standards.

- Automotive: Durable, precision-engineered parts for engines, transmissions, and chassis.

- Electronics: Micro-machined components for high-tech devices and consumer electronics.

- Industrial Machinery: Custom parts capable of withstanding harsh operating conditions.

Why Choose DeepMould.net for Your CNC Machining and Metal Fabrication Needs?

1. Unparalleled Quality and Precision

Our commitment to quality control ensures that every part meets exact specifications. We utilize advanced inspection tools such as coordinate measuring machines (CMM) for meticulous verification.

2. Experienced and Skilled Workforce

Our team comprises seasoned engineers and operators who understand the nuances of CNC programming, tool selection, and process optimization.

3. Comprehensive Service Range

From initial design and prototyping to full-scale production and assembly, we offer a full spectrum of metal fabrication services backed by cnc machining expertise.

4. Advanced Technology for Superior Results

Integration of CAD/CAM software, high-precision CNC machines, and automation tools for streamlined workflow and exceptional accuracy.

5. Competitive Pricing and Fast Turnaround

We optimize manufacturing processes to deliver cost-effective solutions without compromising on quality, ensuring timely delivery to keep your project on schedule.

Steps to Engage DeepMould.net for Your CNC Machining Projects

- Consultation and Design: Share your project specifications or CAD files for evaluation.

- Quote and Planning: We provide a detailed quote with timelines and process insights.

- Manufacturing: Our skilled team utilizes advanced CNC machinery to produce your parts with precision.

- Quality Inspection: Rigorous testing ensures every piece adheres to specified standards.

- Delivery and Support: Swift shipment with ongoing support and potential for further customization.

The Future of Metal Fabrication Powered by CNC Machining

The landscape of metal fabrication is increasingly reliant on cnc machining due to its unmatched ability to produce precise, complex, and durable parts efficiently. Innovations such as multi-axis machining, automation, and AI-driven quality control continue to elevate the capabilities of CNC technology, opening new horizons for manufacturers worldwide.

At DeepMould.net, we are dedicated to staying at the forefront of these advancements, offering customers innovative solutions that keep their products ahead of the competition.

Conclusion: Partner with the Leaders in CNC Machining and Metal Fabrication

Choosing the right partner for cnc machining and metal fabrication is crucial for achieving superior product quality, efficiency, and cost savings. With our extensive experience, cutting-edge technology, and unwavering commitment to excellence, DeepMould.net is your ideal collaborator for all your metal fabrication needs.

Transform your manufacturing process today by leveraging the power of CNC machining. Contact us now to discuss your project and discover how we can turn your ideas into reality with precision, reliability, and unmatched craftsmanship.